- Perovskite processing

Wet- or hybrid-processed perovskite (D3.3, M18 - April 2024)

To develop wet or hybrid processes for perovskite absorbers that yield device-quality and stable layers for scalable wafer formats with reproducible results, PEPPERONI partners compared various deposition methods. The main goal of the performed experiments reported in the deliverable was to achieve a quasi-Fermi level splitting (QFLS) with minimal variation while maintaining a specific optical bandgap. QFLS is a measure of how far the energy states of electrons and holes are pushed apart in an excited semiconductor, showing the energy potential for electrical or optical processes. This concept is crucial for understanding the efficiency of solar cells.

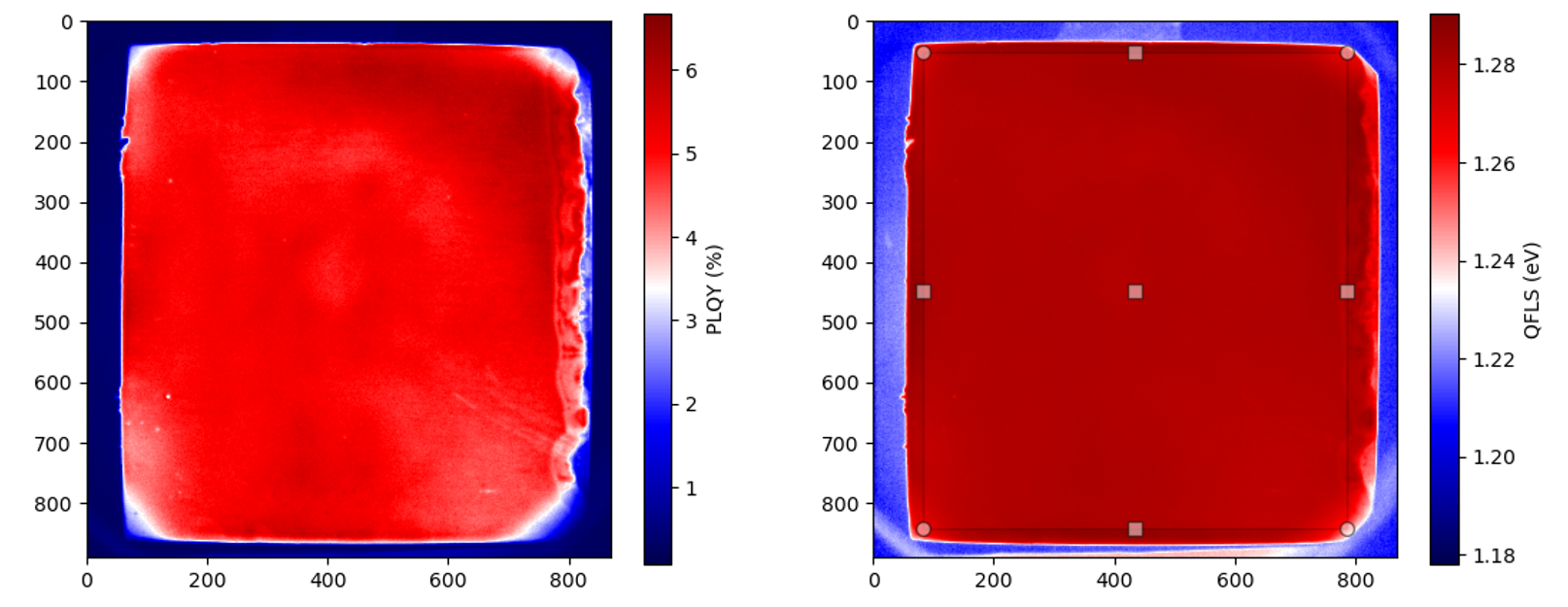

Two deposition techniques were used within the activity: (1) a one-step blade coating process and (2) a two-step method combining physical vapor deposition (PVD) with slot-die coating. After deposition, photoluminescence (PL) imaging was performed across the entire wafer, followed by more localized measurements to map both the PL quantum yield (PLQY) and QFLS values. PLQY is a measure of how efficiently a material emits light when it absorbs energy. A higher PLQY means the material is better at converting absorbed energy into light, which is ideal for creating efficient devices.

The targets were successfully met. The blade coating method resulted in an average QFLS with very low variation and a PLQY that exceeded expectations. This highlights the method’s effectiveness and the material’s potential for high-quality, uniform materials suitable for reliable and efficient solar cells. While the experiments were conducted on M2 wafers instead of M6, the difference in wafer size is small enough that scaling up should not pose significant challenges.