- Tandem technology

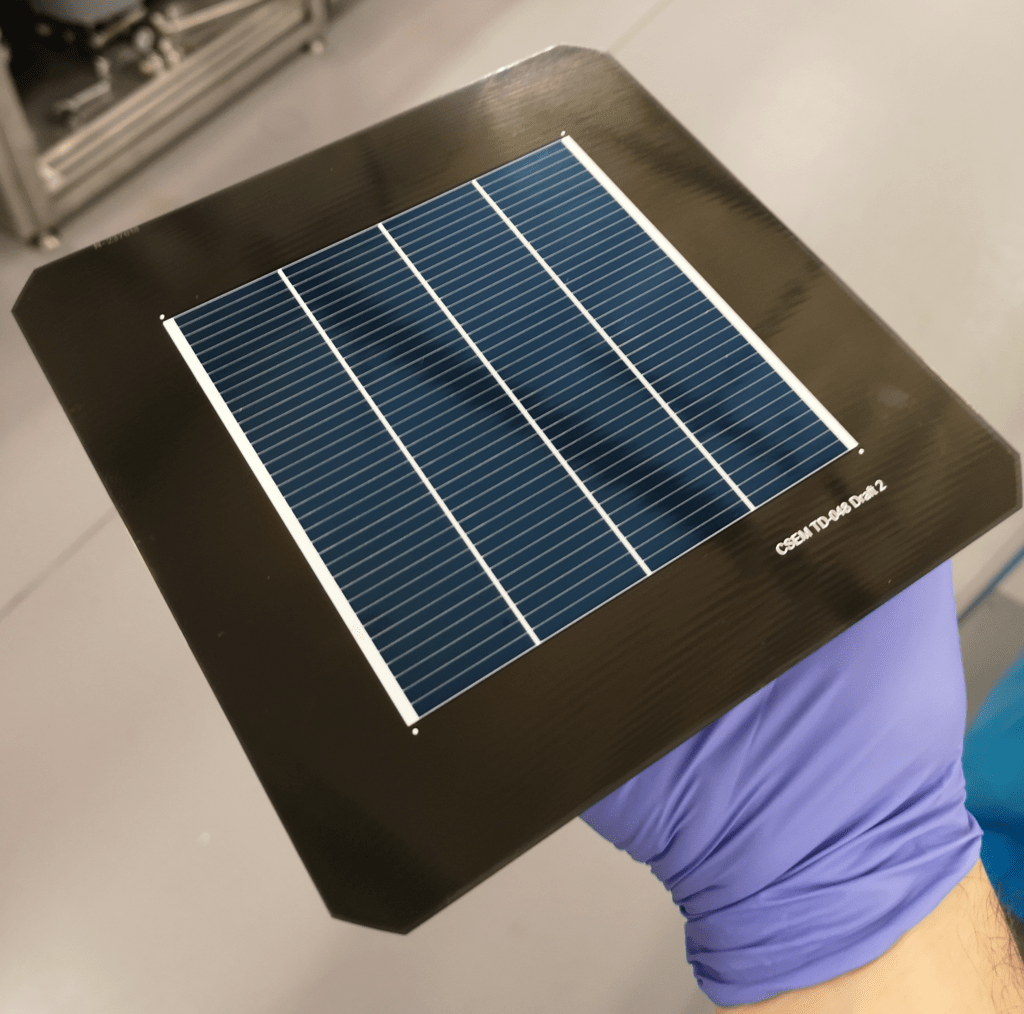

PEPPERONI has selected technology that promises the best ratio of performance over manufacturing costs – silicon/perovskite tandem

- Better together

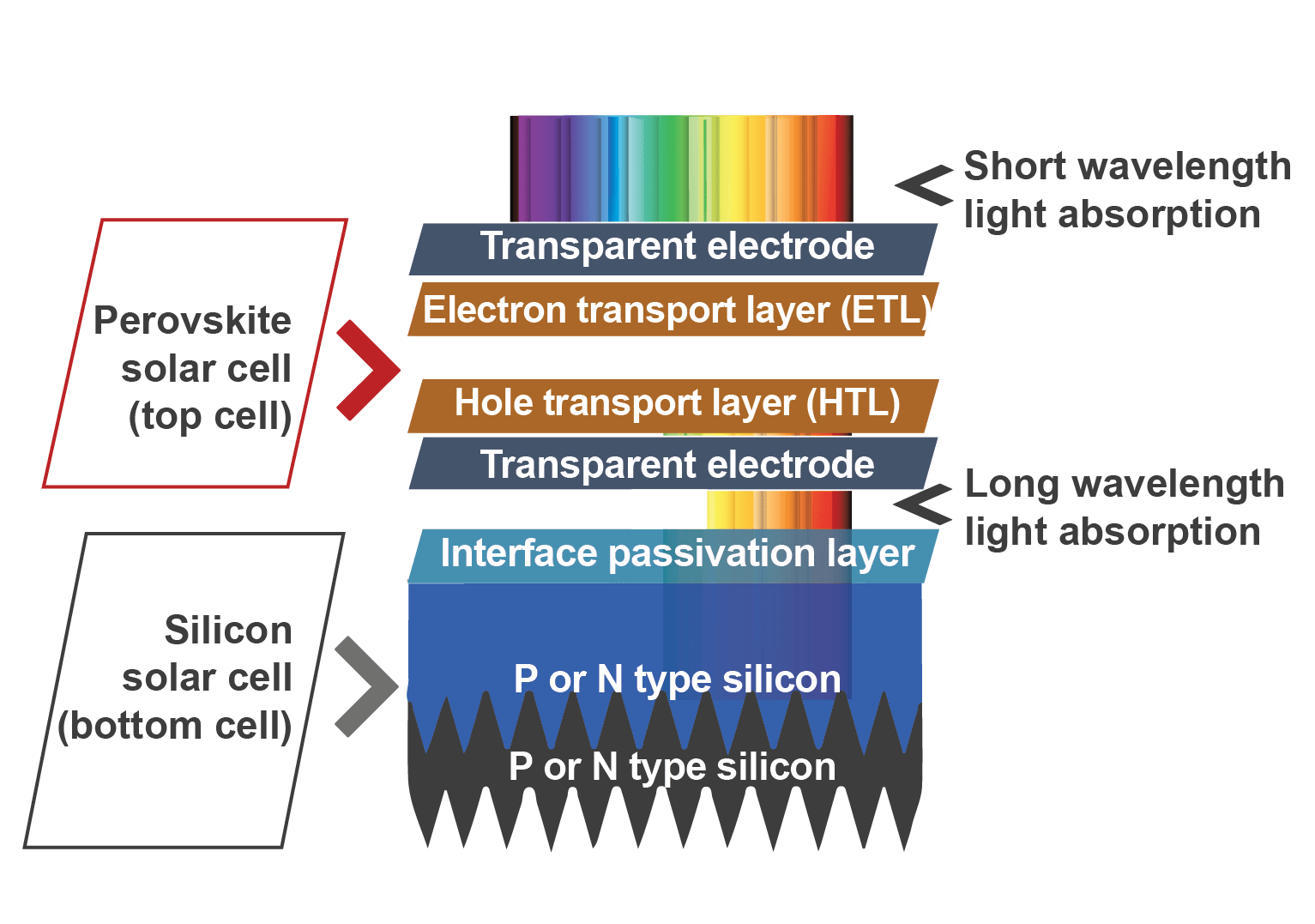

A new generation of low-cost tandem cells is needed to enable widespread implementation. Currently, the most established solar cell technologies are made with silicon and account for more than 90% of the global solar market. Tandem cells exceed the limits of these single-material cells by adding a complementary top perovskite cell to the existing bottom silicon cell, allowing the two materials to work in tandem to boost efficiency.

PEPPERONI will ‘spice up’ industrial silicon cells with a perovskite top cell.

This tandem design benefits from the industrial expertise of silicon PV and extends the range of attainable power conversion efficiency (PCE) beyond the practical limits of silicon. Perovskite can be fine-tuned to take advantage of the parts of the solar spectrum that typical silicon PV materials cannot utilise very efficiently, meaning they make excellent hybrid-tandem partners.

- Boosting efficiency with perovskite

- Solar cells combining two active layers make better use of light than conventional single-layer cells. As a result, such tandem cells yield more electricity per unit area.

- PEPPERONI researchers combine technically optimized silicon and thin-film cells with the latest perovskite technology to achieve record-high efficiencies.

- The efficiency gain of tandem cells promises lower prices and a higher potential for solar power in Europe

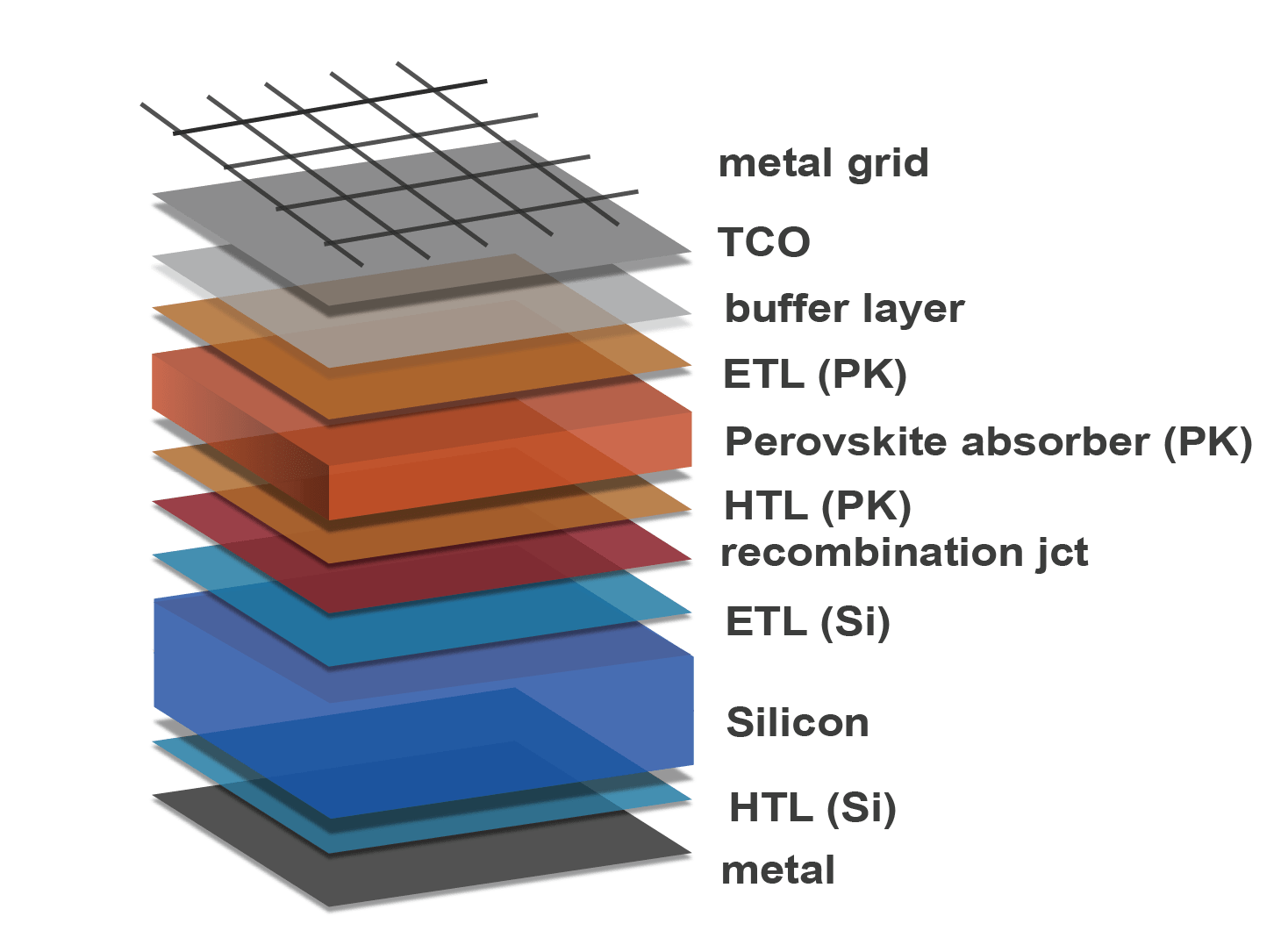

building blocks of the tandem cell stack to make them industry-ready

structure of a perovskite-silicon tandem solar cell

- Key benefits

- higher module efficiencies

- cost-effective production scale up

- low costs of silicon PV

- rapid deployment of this new tandem technology

- Q.ANTUM technology

PEPPERONI proposes to use a type of silicon bottom cell, which is based on technology that is already produced at a gigawatt scale globally: Q.ANTUM technology. This technology was first introduced in 2012 by the project partner leading the technology development, Qcells. This solar module design introduces innovative cell interconnections, allowing for fewer gaps in the row and enabling a higher power density of the solar module, increasing its efficiency by 4% compared to typical silicon-based solar modules in the industry. Q.ANTUM Technology is based on passivated emitter rear-side cell (PERC) technology and offers a number of additional benefits for long-term durability, such as anti-PID, anti-LID and anti-LeTID performance. Read more about the Q.ANTUM technology

Pictures and figures provided by PEPPERONI partners (CSEM, accelopment, Qcells)