- Environmental performance

Eco-design report (D8.3, M26 - December 2024)

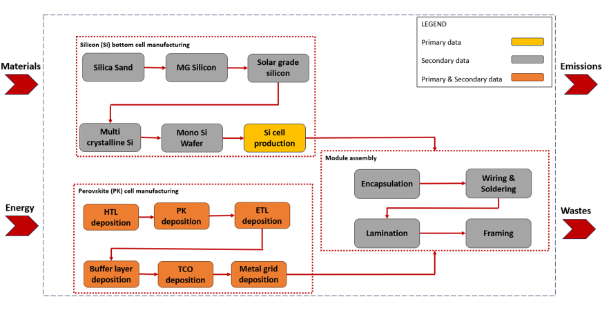

Work Package 8 evaluates the environmental performance of Perovskite/Silicon tandem (PSTC) PV modules manufactured in Europe, focusing on key findings from the Life Cycle Assessment (LCA) performed using the Environmental Footprint 3.1 (EF 3.1) method:

- Silicon cell production: The final wafer-to-cell conversion has the highest impact, mainly due to silver-rich metallisation paste.

- Perovskite top cell manufacturing: The energy-intensive evaporation process, particularly in Stack B2, is a major hotspot. Minimising evaporation usage is crucial, as material consumption has a minor role.

- PV module assembly: Key impact drivers include silver in metallisation paste, solar glass, aluminium alloys, copper, and ethylene vinyl acetate encapsulant.

The environmental impact of producing 1 m² of PSTC module varies depending on the specific architecture of the perovskite cell stacks. For Climate Change, impacts range from 108.2 to 112.1 kg CO₂eq. Resource Use (minerals and metals), driven primarily by silicon cell production and module assembly, is consistent at 0.2 kg Sb eq. Human Toxicity (cancer effects) ranges from 9.43E-08 to 9.58E-08 CTUh, and Water Use from 35.58 to 36.43 m³. Future work will address the usage phase and End-of-Life scenarios, emphasising recycling strategies.

Developed by